Blog: Thermostatic mixing valve- An integrated solution for emergency safety showers and eyewashes

Background

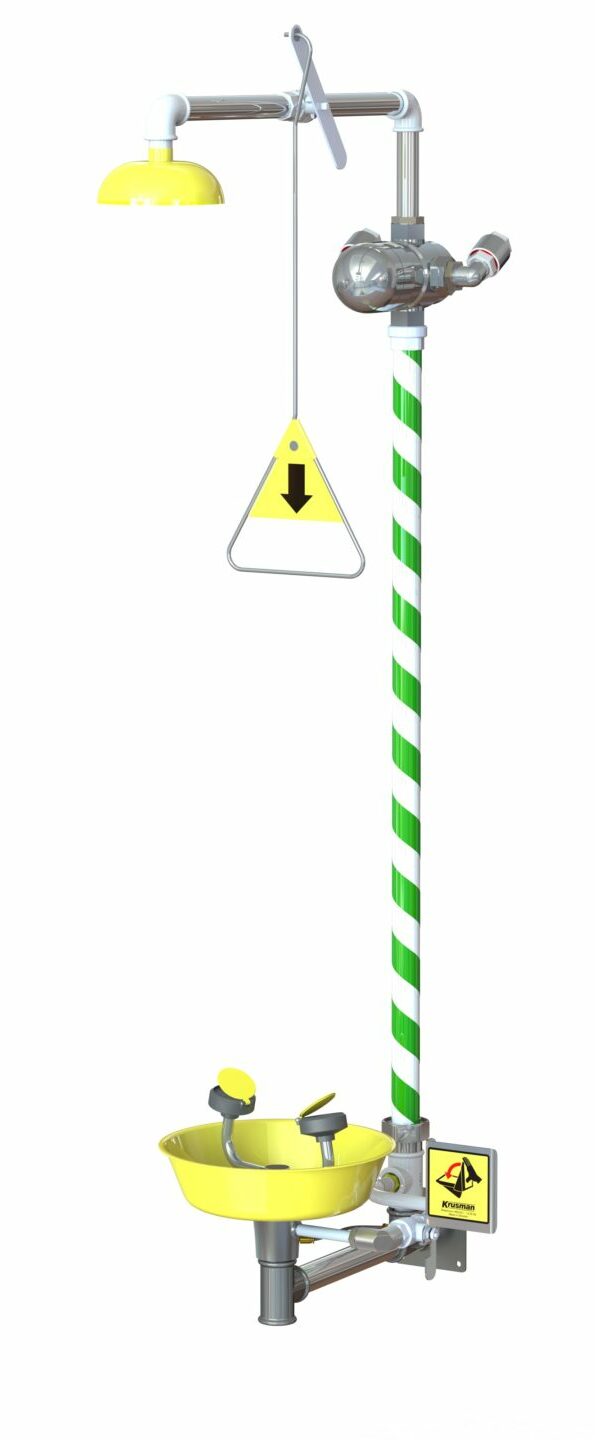

In 2000, Krusman Emergency Showers developed its first integrated-mixing-valve solution. To simplify the installation of emergency safety showers (also known as: emergency shower, safety shower) and eyewash stations, and ensure total water temperature control, mixing valves were integrated into the Krusman emergency shower design. This novelty was driven by the need to exceed international safety standards, as well as to enhance user experience. Unifying the two components minimized complications for the end user- in maintaining recommended water temperatures in their emergency safety shower and eyewash systems.

Challenges

The installation of a thermostatic mixing valve and an emergency safety shower as separate items is operational, but if not done correctly could lead to severe consequences, such as:

- Water temperature: Water in the pipe that sits in-between the mixing valve and shower valve, when stagnant, is not guaranteed to stay at the recommended temperatures required for an emergency shower. It will either cool down or heat up depending on the ambient temperature of the site.

- Risk: Due to this, the risk of Legionella bacteria growth in the pipe that sits in-between the mixing valve and shower valve significantly increases.

- Installation & maintenance: The installation and maintenance of a separated solution is time-consuming, laborious and involves different components/locations, inevitably increasing the risk of plumbing errors.

Having been in the safety shower industry for over 50 years, the Krusman team has collected such pain points from plumbers, installers, and site managers. For these reasons, we developed a line of emergency safety showers that have an integrated thermostatic mixing valve. This allows customers to focus on ensuring optimal temperatures and safety, while simplifying the installation and maintenance process to save time and resources.

Solutions

Krusman conducted extensive R&D to understand the specific needs of safety shower users, and the challenges faced by plumber/installers, at a deeper level. The development focused on 3 major points:

- Firstly, to ensure water is always at a safe, regulated temperature to prevent hypothermia and encourage the user to properly decontaminate themselves for at least 15 minutes (as per ANSI/ISEA Z358.1 and EN 15154-1 to 5).

- Secondly, to reduce or completely prevent Legionella bacteria growth in the pipes sitting in-between the mixing valve and emergency showers.

- Finally, simplify the installation and assembly process for everyone who purchases an emergency shower.

The integration of a thermostatic mixing valve into an emergency safety shower system was engineered to provide superior performance and reliability. The mixing valve Krusman uses in their products is of a sophisticated design, the mechanism in place allows for highly accurate temperature control, and is resistant to any calcification reactions, which is a common point of deterioration and faultiness in mixing valves. Krusman also uses only high-quality materials, guaranteeing:

- Durability

- Minimum maintenance requirement

Regulatory Compliances

In order to maintain user safety and regulatory adherence, Krusman’s integrated emergency solution was designed to comply with the following international safety standards:

- EN 15154-1 to 5: latest edition

- The principal factors in providing first aid treatment, as per the EN norms, require continuous and timely irrigation of affected tissues for the recommended irrigation period with tepid water.

- Water should be between 15°C and 37°C, ideally 20°C to 25°C.

- Temperatures above 37°C can harm the eyes and skin, while prolonged exposure to cold water can lead to hypothermia, prematurely halting treatment.

- Emergency safety showers must deliver a consistent flow for at least 15 minutes, in line with national regulations. These showers are designed to immediately flush the body to extinguish flames or wash off harmful substances, minimizing further injury before medical help is sought.

- ANSI/ISEA Norm Z358.1- latest edition

- The medical guidelines that ANSI norms are based on recommend using tepid water, temperatures between 16 °C and 38 °C for flushing chemically injured tissues.

- Temperatures above 38°C can accelerate chemical reactions, causing harm to the eyes, while very cold water can cause hypothermia if used for too long and reduce the likelihood of adequate flushing time.

- Effective first aid relies on maintaining continuous and appropriate-temperature irrigation for at least 15 minutes.

- Delivering tepid water to emergency equipment typically requires supplying both hot and cold water to the unit and installing a mixing valve to achieve the desired temperature.

The Krusman Benefit

The integrated emergency safety shower is not just a product but involves a whole solution. This solution guarantees the Krusman Benefit:

- Quality assurance

- Hydrostatic test and leak test: Each integrated safety shower undergoes rigorous QA/QC tests in Krusman’s factory. This ensures that every unit shipped out is of the highest quality, with no leaks and reliable performance under pressure.

- Semi assembled products: Krusman’s products are either semi-assembled or fully assembled. This significantly reduces the time and effort required for installation, ensuring a faster, smoother and more accurate

- Servicing efficiency

- Ease of installation: The integrated design simplifies the installation process by eliminating the need to separately install and connect a mixing valve. Installers only need to connect the hot and cold-water inputs.

- Reduced maintenance: The integrated system ensures that maintenance tasks are streamlined, as all components are designed to work together seamlessly. This reduces the likelihood of issues and makes any necessary repairs easier to perform.

- Compliance with Regulations: By providing a reliable, integrated solution, Krusman ensures that users meet all relevant safety standards, such as ANSI/ISEA Z358.1, EN 15154-1 to 5. This reduces the risk of non-compliance during safety audits.

- Credibility

- Enhanced user experience: The precise temperature control provided by Krusman’s mixing valve ensures that water is always at a comfortable and safe temperature, encouraging users to stay under the shower for the recommended duration and ensuring effective decontamination.

- Reliability: The use of sophisticated components, and premium materials ensures maximum durability.

All Krusman Integrated Products

The following list covers all integrated emergency safety shower and eyewash options available today, at Krusman:

- (Stainless steel) emergency shower and eyewash station range: Click here

- (Standard- galvanized steel) emergency shower and eyewash station range:Click here

- (Stainless steel) emergency shower: Click here

- (Standard- galvanized steel) emergency shower: Click here

Conclusion

Krusman’s integrated emergency shower with a thermostatic mixing valve solution demonstrates the company’s commitment to safety, knowledge, and quality. By addressing the challenges of a non-integrated solution and complying with international safety standards, Krusman offers the industry a product that is not only easier to install and maintain but also ensures optimal performance and user safety.

Interested in knowing more? Contact us today!